DYPHOX Technology

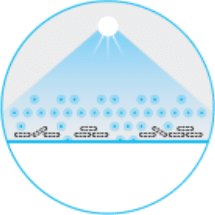

How DYPHOX Works…

The Dyphox hygiene solution when applied to a surface, Can kill multi resistant bacteria (MRSA), viruses (Corona Virus).

It can achieve this by using ambient light and its surrounding Oxygen. Dyphox continues to self-disinfect for 12 months.

The clear Universal coating, which can be wiped or sprayed on retroactively, permanently closes hygiene gaps to optimally protect employees and customers.

The unique operating principle ensures consistent Effectiveness on both dry and moist surfaces.

This makes Dyphox the only anti-microbial surface coating proven to work under real world conditions. ISO 21702 (modified).

The long lasting self-sanitising effect will continue to work for 12 months.

| DYPHOX In More Detail | |

|---|---|

| Type Of Coating | |

| Application | |

| Duration | |

| Effectiveness | and ISO 21702 (mod) |

| Field Study | |

| Suitable Materials | |

| Safety | |

| Environment | |

| Surfaces | |

| Product Characteristics | |

|---|---|

| It’s a clear liquid solution. | |

| Plastics, glass, aluminium, lacquered finished furniture & stainless steel. | |

| Can be applied by special cloth or sprayed. | |

| -20 to 80 degrees Celsius and ISO 21702 (mod) |

|

| 0 to 100% | |

| Resistant to common cleaning product & disinfecting agents. | |

Field Study In 2 German Hospitals

The Dyphox Coatings

The Dyphox coatings were tested for the first time in a large- scale field study In two hospitals in Regensburg, Germany. As part of that study, various surfaces Were treated either with an anti-microbial coating or a control coating. Over several months, the number of bacteria on the active & control surfaces Was determined & compared.

Hygiene Plan

Meanwhile, everyday clinical operations continued, & routine cleaning & disinfection of the surfaces were carried out & unchanged according to the hygiene plan.

Ultimately, the evaluation provided a clear result. The Dyphox coatings were able to reduce the risk of high germ contamination on surfaces by up to 67%.

The results of this field study were recently published in the internationally renowned Journal of Hospital infection.

Quellen

Eicher et al., Novel photodynamics coatings reduce the bioburden on near – patient surface thereby reducing the risk for onward pathogen transmission – a field study in two hospitals. Journal of hospital Infection, 2019. 104 (1): 85-91 https://pubmed.ncbi.nlm.nih.gov/31369806/

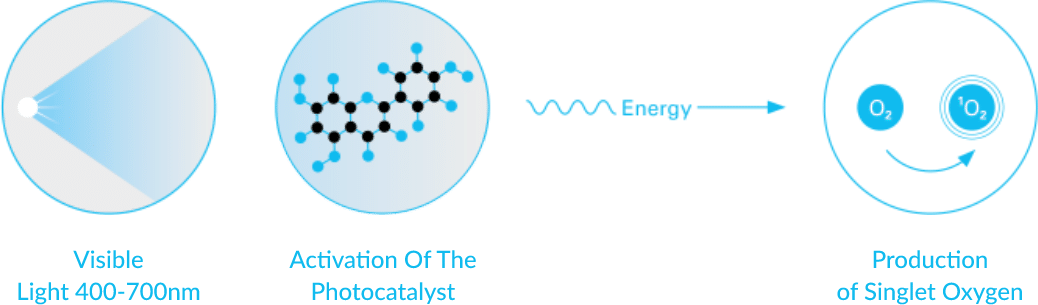

The Science Behind The Product

The antimicrobial effectiveness of Dyphox is based on the principle of Photodynamics, Photodynamics use special photocatalysts that absorb light in the visible light range (400–700 nm this normal light room light). Photodynamics have been used successfully for years in cancer therapy, dentistry & ophthalmology, and in the disinfection of blood stocks.

DYPHOX has identified photocatalysts that absorb light in the visible range. Using this photocatalyst the DYPHOX coating can produce singlet oxygen with an efficiency of up to 99%. Giving the Dyphox coating the ability to safely introduce this technology to everyday surfaces.

When Dyphox has been applied to a surface and there is visible light available, the oxygen above the surface is energized. This gives the oxygen the ability to oxidise the germ shells and thereby destroying them.

Surface is coated with Dyphox

Contamination with bacteria, viruses by contact

Activation of the antimicrobial effect by visible light & oxygen

Fast & effective inactivation of microorganisms-hyfiene gaps are permanently closed

Compared to other technologies, no moisture is required to effectively kill germs. Therefore, Dyphox is particularly suitable for the anti-microbial treatment of surfaces which are usually dry.

There is no resistance to singlet oxygen known to date and there is none to be expected, due to the non-specific mechanism of action. This is particularly important in light of the increase in Multi-resistant bacterial strains in recent years. (Super Bugs)

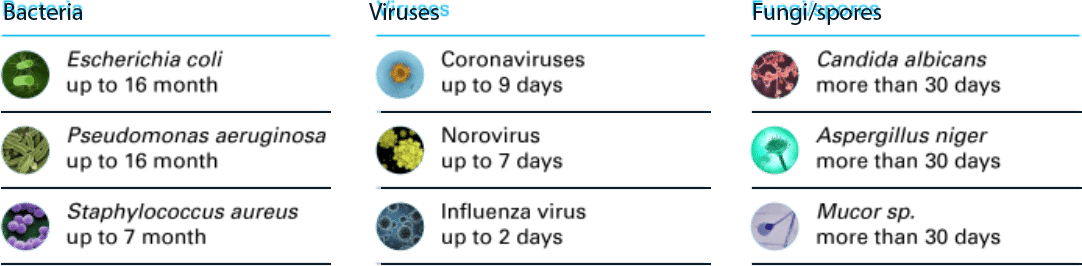

Survival Time Of Bacteria, Viruses, Spores & Fungi On Dry

Surfaces Range From Days To Months.

Standard operating procedures (SOPs) and hygiene plans ensure regular

cleaning and disinfection of surfaces.

- Manual disinfection is only effective at the time of application.

- Dyphox retro coating makes it possible to close the hygiene gaps.

- Recontamination between disinfection cycles is hard to prevent.

- it has been clinically proven to reduce the risk of high bacterial loads & reduce transmission on surfaces.

Antimicrobial Efficacy

Kills more than 99.99% of bacteria (tested after a modified version of ISO 22196)

- Staphylococcus aureus

- Acinetobacter baumannii

- Enterococcus faecium

Kills more than 99.98% of enveloped viruses (tested after a modified version of ISO 21702)

- Influenza A Virus (H1N1)

Kills more than 99.99 % of coronavirus (tested after a modified version of ISO 21702)

- TGEV-Coronavirus

Kills more than 99% of non-enveloped viruses (tested after a modified version of ISO 21702)

- Adenovirus (same test category as Noroviruses)

Field study in two hospitals with 1300 samples over 9 months

Certificates

Dermatest

Skin compatibility dermatologically approved – very good

ISEGA

Food contact certificate of compliance for coated surfaces

ISEGA

Perspiration and saliva proof properties

DEKRA report

No emission of volatile organic compounds,

Surface Disinfection At A Glance

| Dyphox | Ag/Cu/Zn | TiO2 | UV-C | Biocides | |

|---|---|---|---|---|---|

| Effective under dry conditions |  |

|

|||

| Effective under wet conditions |  |

|

|

|

|

| No development of resistances |  |

|

|

||

| Activated by visible light |  |

||||

| Activated by UV light |  |

|

|

||

| No leaching of nanoparticles or chemicals |  |

|

|||

| Harmless of humans |  |

||||

| Eco friendly |  |

||||

| No accelerated aging of plastics |  |

|

|

Comparison Of Methods For Surface Disinfection

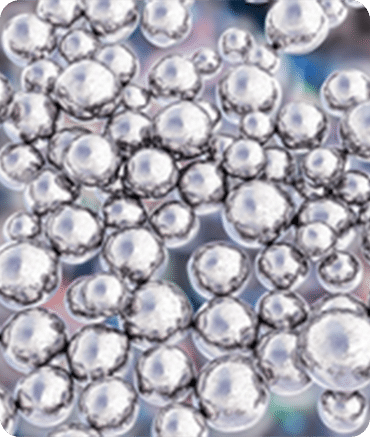

Silver/copper/zinc-treated Surface Coatings

Silver, copper and zinc ions have antimicrobial properties. Silver is used, for example, in the antimicrobial treatment of wound dressings or bladder catheters. This makes sense because both are used in moist conditions. Only liquid enables the efficient transport of the ions to the germs and thus the antimicrobial effectiveness. Metal ions and particles are less suitable for surface application, as their effectiveness is very much reduced under dry conditions. Particles are also continuously released into the environment and there have been multiple reports of resistance development.

Titanium Dioxide-treated Surface Coatings

The antimicrobial effectiveness of titanium dioxide is based on the compound’s photocatalytic effect. By activating titanium dioxide with UV-A (315–380nm) irradiation, radical oxygen species such as the hydroxyl and superoxide radical are formed. These reactive oxygen species (ROS) can efficiently inactivate germs. However, the higher reactivity of the radical oxygen species will also attack plastic surfaces over the long term. UV-A radiation also penetrates the tissue layers of the skin and the eye and damages them. Their use in surface technology is therefore only possible in accordance with safety conditions.

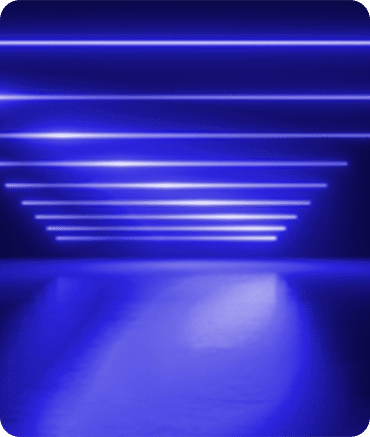

Surface Disinfection With UV-C Radiation

The antimicrobial effect of UV-C radiation is based on damage to the genetic information of bacteria and viruses. The high-energy, short-wave light induces strand breaks in the nucleic acid chains and thus causes a bacteriostatic or virustatic effect. UV-C irradiation can be used, for example, for the chemical-free disinfection of water systems. Similarly, to the use of titanium dioxide, the use of UV-C radiation to disinfect surfaces is only possible under certain safety conditions.

Surface Disinfection Using Biocides

The antimicrobial effect of biocides such as benzalkonium chloride, triclosan, isothiazolinones or chlorhexidine comes from “poisoning” the germs. Any concentration of these toxic substances in the ecosystem or human body should be avoided as far as possible. The permanent treatment of surfaces with classical biocides is therefore concerning. There is also only limited effectiveness on dry surfaces. The RKI also strongly advises against the widespread use of biocidal agents such as triclosan, chlorhexidine and benzalkonium chloride, as clinically relevant germs have been shown to develop strong and stable resistance to these agents. The development of cross-resistance to antibiotics is also well known and very worrying.

Comparison Of Methods For Surface Disinfection

Silver/copper/zinc-treated Surface Coatings

Silver, copper and zinc ions have antimicrobial properties. Silver is used, for example, in the antimicrobial treatment of wound dressings or bladder catheters. This makes sense because both are used in moist conditions. Only liquid enables the efficient transport of the ions to the germs and thus the antimicrobial effectiveness. Metal ions and particles are less suitable for surface application, as their effectiveness is very much reduced under dry conditions. Particles are also continuously released into the environment and there have been multiple reports of resistance development.

Titanium Dioxide-treated Surface Coatings

The antimicrobial effectiveness of titanium dioxide is based on the compound’s photocatalytic effect. By activating titanium dioxide with UV-A (315–380nm) irradiation, radical oxygen species such as the hydroxyl and superoxide radical are formed. These reactive oxygen species (ROS) can efficiently inactivate germs. However, the higher reactivity of the radical oxygen species will also attack plastic surfaces over the long term. UV-A radiation also penetrates the tissue layers of the skin and the eye and damages them. Their use in surface technology is therefore only possible in accordance with safety conditions.

Surface Disinfection With UV-C Radiation

The antimicrobial effect of UV-C radiation is based on damage to the genetic information of bacteria and viruses. The high-energy, short-wave light induces strand breaks in the nucleic acid chains and thus causes a bacteriostatic or virustatic effect. UV-C irradiation can be used, for example, for the chemical-free disinfection of water systems. Similarly, to the use of titanium dioxide, the use of UV-C radiation to disinfect surfaces is only possible under certain safety conditions.

Surface Disinfection Using Biocides

The antimicrobial effect of biocides such as benzalkonium chloride, triclosan, isothiazolinones or chlorhexidine comes from “poisoning” the germs. Any concentration of these toxic substances in the ecosystem or human body should be avoided as far as possible. The permanent treatment of surfaces with classical biocides is therefore concerning. There is also only limited effectiveness on dry surfaces. The RKI also strongly advises against the widespread use of biocidal agents such as triclosan, chlorhexidine and benzalkonium chloride, as clinically relevant germs have been shown to develop strong and stable resistance to these agents. The development of cross-resistance to antibiotics is also well known and very worrying.

Contact Us

Would you like to get a quote?

To learn more about our products & services,

here is what you do next